IMC Stainless steel magnetic driven chemical process pump

- Model Number: IMC50-32-125

- Brand Name: kenshine-pump

- Place of Origin: Shanghai, China

- Minimum Order Quantity: 1set

- Supply Capacity: 300sets per month/month

- Payment: T/T in advance

- MemberShip: Free Member

- Inquiry Now

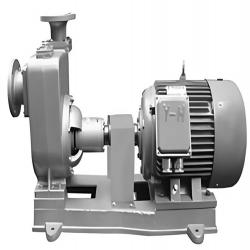

IMC50-32-125 IMC Stainless steel magnetic driven chemical process pump Description

IMC magnetic driven chemical process pump

IMC series magnetic pump is a horizontal cantilever, single stage single suction, magnetic driven standard chemical process pump and suitable to convey flammable, explosive, and corrosive media.

IMC metal stainless steel magnetic pump: The magnetic pump is composed of three parts: pump, magnetic driver, and motor. The key component of the magnetic actuator is composed of an external magnetic rotor, an internal magnetic rotor, and a non-magnetic isolation sleeve. When the electric motor drives the outer magnetic rotor to rotate, the magnetic field can penetrate the air gap and non-magnetic substances, driving the inner magnetic rotor connected to the impeller to rotate synchronously, achieving contactless transmission of power and converting the dynamic seal into a static seal. Due to the complete sealing of the pump shaft and inner magnetic rotor by the pump body and isolation sleeve, the problem of "running, emitting, dripping, and leaking" has been solved, and the safety hazards of flammable, explosive, and harmful media leaking through the pump seal in the refining and chemical industry have been eliminated, effectively ensuring the physical and mental health and safe production of employees. Due to the use of stainless steel and fluoroplastics as the flow components of the pump, corrosion resistance is achieved. The magnetic coupling of the pump is combined with the pump body, resulting in a compact structure, convenient maintenance, and safe and energy-saving. The magnetic coupling of the pump can provide overload protection for the transmission motor.

Working conditions of IMC stainless steel magnetic pump:

Magnetic pumps transport fluids with a density not exceeding 1300kg/m3 and a viscosity not exceeding 3-6m3/s that do not contain ferromagnetism or fibers. The rated temperature of a conventional magnetic pump is made of metal or f46 lining, with a maximum operating temperature of 80 ℃ and a rated pressure of 1.6 MPa; The operating temperature of the high-temperature magnetic pump is ≤ 350 ℃; For pumps made of non-metallic materials, the maximum temperature shall not exceed 60 ℃, and the rated pressure shall be 0.6 MPa.

For liquids with a medium density greater than 1600kg/m3, magnetic couplings need to be designed separately.

The bearings of the magnetic pump use the transported medium for lubrication and cooling, so it is strictly prohibited to operate the magnetic pump without load.

| flow rate | 2-100m3/h |

|---|---|

| pressure | 5-80m |

| pump material | SS304,SS316,SS316L |

| magnetic drive pump | centrifugal chemical pump |

| chemical process pump | industrial pump |

| stainless steel pump | transfer pump |

| circulaiton pump | horizontal centrifugal pump |

| kenshine-pump | china pump |

Retaled category: Magnetic Drive Pump

Hot search: magnetic pump, chemical pump, industrial pump, process pump, stainless steel pump, centrifugal pump