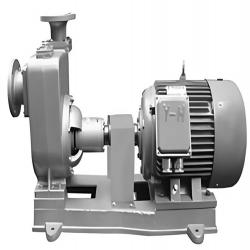

GMZ high efficiency wear resistant slag slurry pump

- Model Number: GMZ40-10-15

- Brand Name: kenshine-pump

- Place of Origin: Shanghai, China

- Minimum Order Quantity: 1Set

- Supply Capacity: 500Sets per month/month

- Payment: T/T IN ADVANCE

- MemberShip: Free Member

- Inquiry Now

GMZ40-10-15 GMZ high efficiency wear resistant slag slurry pump Description

GMZ high-efficiency wear-resisting slag slurry pump

GMZ high efficiency wear-resisting slurry pump is single stage single suction, axial suction cantilever horizontal centrifugal pump. It can be widely used in metallurgy, mining, electric power, coal mine, water conservancy, chemical industry, light industry, petroleum and other departments to transport strong abrasive slurry, high concentration slurry and other corrosive slurry with the large solid particles.

1. The flow parts of GMZ high-efficiency wear-resistant slurry pump are made of high-strength wear-resistant material. It is suitable for conveying slurry with strong abrasion, high concentration, and large particles. It can be used in series at multiple levels within the maximum working pressure range of the pump.

2. GMZ wear-resisting slag slurry pump has interchangeable flow components of various materials according to the different medium. It is suitable for conveying abrasive or corrosive, large or fine particles slurry.

Model description:

For example, GMZ65-20-40

GMZ -- High-efficiency wear-resisting slag slurry pump

65 -- Outlet diameter (65mm)

20 -- Head (20m)

40 -- Flow rate (40m3/h)

Performance range:

flow rate: 8-2600m3/h

Head: 9-150 m

Power: 1.5 -630 kw

Structure:

1. Pump head: GMZ slag slurry pumps have the double pump housing structure. It includes front pump housing, rear pump housing and parts with replaceable flow parts (including impeller, volute, front guard plate and rear guard plate).According to the working pressure, the front and rear pump housing is made of gray cast iron or ductile cast iron, which is vertically open and bolted. The rear pump housing is provided with a stop and bracket to be bolted. The pump outlet can be installed in rotation according to eight angles. Each type of pump inlet is horizontal direction. Viewed from the motor end ,the pump is for clockwise rotation .

2. Shaft seal: three types including auxiliary impeller shaft seal, packing seal and mechanical seal.

(1) Auxiliary impeller shaft seal: when the positive pressure value at the pump inlet is no more than 10% of the pump outlet pressure value, a single-stage pump or a multistage series third-stage pump can be used to seal the auxiliary impeller shaft seal. The auxiliary impeller shaft seal has the advantages of non-dilution pulp and good sealing effect, etc.

(2) Packing shaft seal: Packing shaft seal is simple in structure and convenient in maintenance. It is necessary to use shaft seal to seal water. It can be used in working conditions that are not suitable for auxiliary vane wheel shaft seal and pump suction working conditions.

(3) Mechanical seal: The working conditions is not suitable for the above two kinds of shaft seals, mechanical seal is adopted to reduce the maintenance times of shaft seals.

3. Transmission part: GMZ slag slurry pump adopts the same transmission, including bracket and bearing assembly. The pump shaft diameter is large, the rigidity is good, the cantilever is short, and it will not bend and vibrate under bad working conditions. The bearing adopts single row tapered roller bearing and angular contact ball bearing, which can bear the maximum axial and radial load of the pump. The bearing is lubricated with lithium base grease. Good grease adhesion, not easy to lose, long use time. The sealing is simple, the bearing body is equipped with sealing end cover at both ends, which can effectively prevent the mineral slurry and other dirt from entering the bearing.

| flow rate | 8-2600m3/h |

|---|---|

| head | 9-150m |

| pump material | cast iron,ductile iron, high chrome alloy |

| centrifugal pump | sewage pump |

| slurry pump | wastewater pump |

| pulp pump | industrial pump |

| wear resistant pump | effluent pump |

| kenshine-pump | china pump |

Retaled category: Chemical Pump

Hot search: slurry pump, sewage pump, pulp pump, wastewater pump, centrifugal pump, industrial pump